What Is Pipe Bedding Sand?

Pipe bedding sand plays a crucial role in underground pipe installation, providing support, stability, and protection for various types of pipelines. It's a carefully selected and processed granular material placed around and beneath buried pipes to create a stable and even foundation. Understanding its properties and function is essential for ensuring the longevity and proper operation of underground pipe systems.

The primary purpose of pipe bedding sand is to distribute the load imposed on the pipe evenly across the foundation. This prevents pressure points from forming, which can lead to cracking, deformation, or even pipe failure over time. The consistent support offered by the sand layer minimizes the risk of damage from ground movement, settling, or external forces.

Beyond load distribution, pipe bedding sand also contributes to proper drainage around the pipe. Its porous nature allows water to flow freely, preventing the buildup of hydrostatic pressure, which can exert significant stress on the pipe. Efficient drainage also safeguards against soil erosion and washout around the pipe, further enhancing its stability.

Not all sand is suitable for pipe bedding. Specific characteristics are essential for effective performance. Pipe bedding sand typically consists of either natural or manufactured sand with distinct properties. Natural sands are derived from geological sources and may require processing to meet the necessary specifications. Manufactured sands, often crushed stone or gravel, offer a more controlled and consistent product.

Regardless of the source, pipe bedding sand must adhere to certain standards. Gradation, or the distribution of particle sizes, is a critical factor. A well-graded sand contains a range of particle sizes, allowing for optimal compaction and density. This creates a stable foundation that minimizes voids and maximizes load-bearing capacity. Specifications often define acceptable ranges for different particle sizes within the sand.

Cleanliness is another crucial aspect. Pipe bedding sand should be free from organic matter, clay, silt, and other impurities that can compromise its structural integrity and drainage capabilities. Organic materials can decompose, creating voids and instability, while clay and silt can hinder water flow and lead to excessive pressure buildup around the pipe.

Angularity, or the shape of the sand particles, influences the sand's ability to interlock and compact effectively. Angular particles generally provide better stability than rounded particles, creating a denser and more resistant bedding layer. Specifications may define acceptable angularity ranges for optimal performance.

The selection of appropriate pipe bedding sand depends on several factors, including pipe material, soil conditions, and the anticipated load on the system. For instance, flexible pipes like PVC may require a different bedding material than rigid pipes like concrete or ductile iron. Similarly, challenging soil conditions, such as expansive clays or highly permeable soils, necessitate careful consideration of the bedding material's properties.

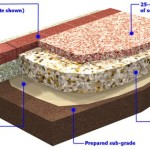

Proper installation of pipe bedding sand is crucial for its effectiveness. The trench bottom should be prepared and compacted before placing the sand. The sand is then typically placed in layers and compacted to achieve the desired density. Proper compaction ensures uniform support and minimizes settling. The depth and width of the sand layer depend on the pipe diameter and the project specifications.

Different types of pipe bedding sand cater to specific applications. Coarse sands are often preferred for drainage applications, while finer sands may be used for bedding smaller diameter pipes. In some cases, a combination of sand and gravel may be employed to achieve optimal performance. Certain projects may also utilize specialized bedding materials designed for specific pipe materials or challenging soil conditions.

Regular inspection and maintenance of underground pipe systems are essential for ensuring their long-term functionality. While pipe bedding sand provides crucial support and protection, periodic inspections can help identify potential issues, such as settlement, erosion, or contamination, allowing for timely intervention and preventing costly repairs or failures.

The use of high-quality pipe bedding sand is a crucial investment in the longevity and reliability of underground pipe systems. Its ability to distribute loads, facilitate drainage, and protect pipes from external forces contributes significantly to the overall performance and lifespan of the infrastructure. By carefully selecting and installing the appropriate bedding material, engineers and contractors can ensure that underground pipelines operate efficiently and effectively for years to come.

Understanding the properties and function of pipe bedding sand is fundamental for anyone involved in the design, installation, or maintenance of buried pipelines. Its role in providing a stable and protective environment for these essential systems cannot be overstated. Proper selection and installation of pipe bedding sand are essential for ensuring the long-term performance and integrity of underground infrastructure.

Pipe Bedding Sand Whibco

Know How To Meet Bedding Regulations Master Plumbers

Pipe Bedding Material

Pipe Bedding Sand Cootes Quarry S

Drain And Pipe Granular Bedding

Cross Section Of Pipe Bedding Scientific Diagram

Bedding Sand Acme Gravel

Pipe Bedding Sand And Gravel Groundwork Contractors Herefordshire

Drain And Pipe Granular Bedding

Recycled Pipe Bedding Sand Boral

Related Posts